2025-04-11 17:42:49

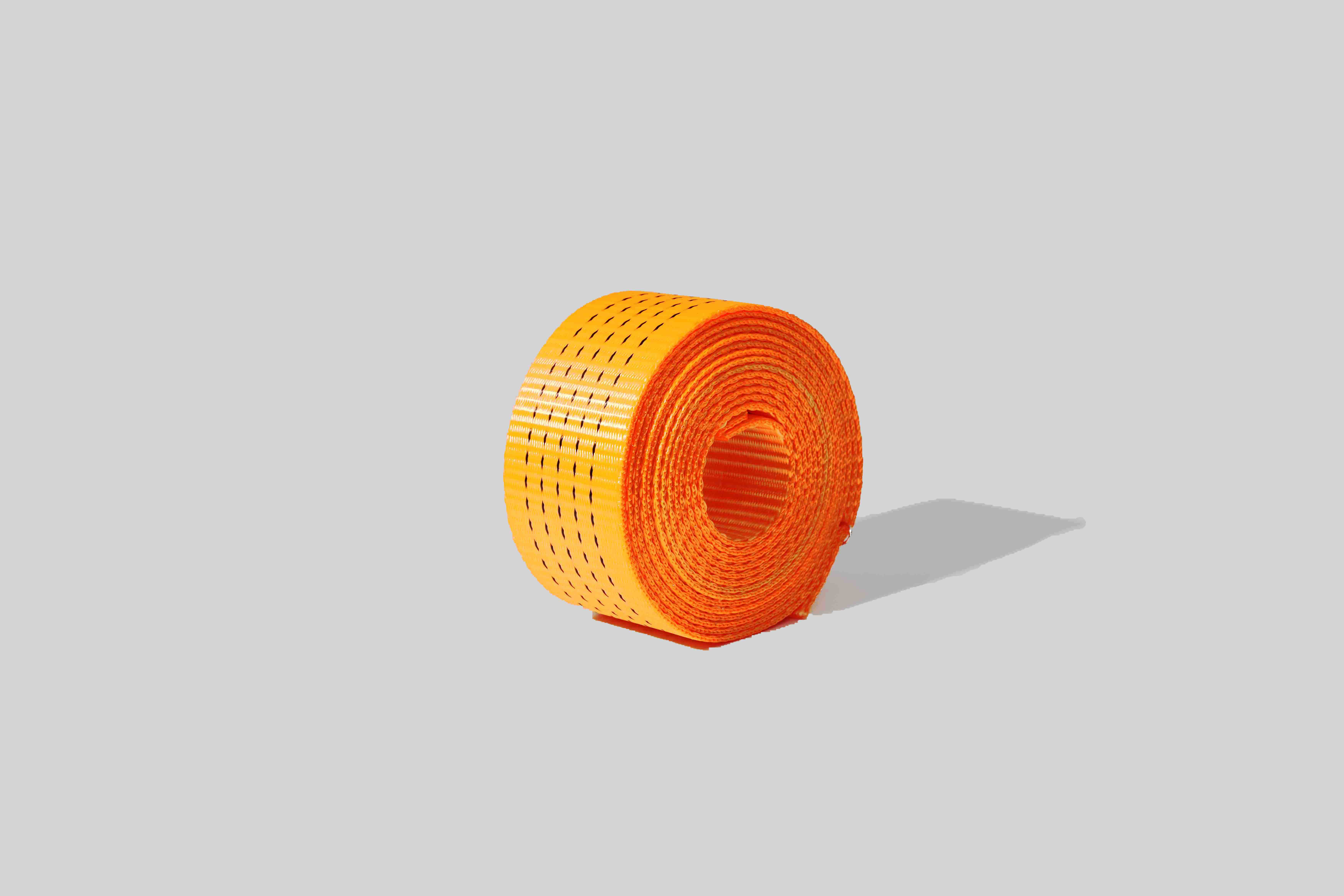

Industrial Sling Webbing is a fabric used for lifting, handling and fixing heavy objects. It is usually made of strong fiber materials such as polyester (PET), nylon (PA), etc., with high wear resistance, strength and toughness. It is mainly used in industries, construction, warehousing, transportation and other fields, and plays a key role in the lifting process of heavy objects. Sling webbing is usually formed by weaving or sewing processes. Common forms include single-layer and multi-layer webbing, and can be designed into various widths and lengths as needed.

Material:

Polyester (PET): Polyester sling webbing is one of the most common materials, with the advantages of high strength, tensile resistance, wear resistance and chemical corrosion resistance. Polyester Webbing can withstand higher loads and has stable performance in humid environments.

Nylon (PA): nylon webbing is softer and more elastic than polyester webbing, suitable for applications that require greater flexibility and elongation. Nylon webbing has poor UV resistance, but it performs well in low temperature environments.

Polypropylene (PP): Polypropylene webbing is usually used for lifting lighter loads and has good water resistance and UV resistance. It is cheaper than polyester and nylon, but has a lower load-bearing capacity.

Ultra-high molecular weight polyethylene (UHMWPE): This material is lighter and very strong than polyester and nylon, but it is more expensive. It is usually used in applications that require super strong load-bearing capacity and have a large weight limit.

Uses:

Lifting and handling heavy objects: This is the most important use of sling webbing, which is widely used in construction, warehousing, transportation and other fields for lifting large equipment, cargo, structural parts, etc.

Lifting ships and offshore engineering: In offshore platform construction, ship repair and offshore lifting operations, sling webbing is often used to safely lift and secure equipment and cargo.

Machinery and equipment transportation: Industrial sling webbing provides a reliable lifting solution in equipment relocation and machinery transportation. Due to its soft nature, it can adapt well to irregularly shaped objects.

Guardian: Some industrial sling webbing is also used for equipment protection to avoid scratches or damage to the surface of the equipment during lifting.

Used for erecting and hoisting large pipes, steel, etc.: In construction projects, sling webbing is widely used to hoist heavy objects such as steel materials, building structures and pipes.

Features:

High-strength load-bearing capacity: Industrial sling webbing is made of high-strength fiber and has extremely high tensile strength. It can withstand tons or even tens of tons of weight to ensure the safety of heavy lifting.

Softness and flexibility: Compared with hard lifting tools such as wire Ropes, webbing has better softness and can avoid scratching the surface of objects.

Wear and weather resistance: High-quality polyester, nylon and other materials have strong wear resistance and can withstand high-frequency use and harsh weather environments.

Lightness: Compared with metal slings, sling webbing is lighter, easier to carry and use, and takes up less space when stored.

UV resistance: Some webbing materials (such as polyester) have good UV resistance, which can effectively resist sunlight and extend service life.

Chemical corrosion resistance: Polyester and other materials can also maintain good performance in acid and alkali environments, and are suitable for lifting operations in chemicals or wet environments.

Advantages:

High safety: Due to the softness of the sling webbing, it will not cause damage to the hoisted object, especially when hoisting precision instruments or fragile items.

Easy operation: Compared with the traditional wire rope hoisting method, the operation of the sling webbing is easier, and workers can complete the hoisting work by simple knotting, hooking, etc., which reduces the difficulty of operation.

Strong durability: High-quality industrial sling webbing can withstand high-frequency use, and is wear-resistant, aging-resistant, and has a long service life.

Versatility: The sling webbing can provide customized services according to different load requirements and is suitable for various lifting tasks, including heavy machinery, building materials, and high-value items.

FAQ:

How to choose the right industrial sling webbing?

When choosing, consider the load capacity, material (such as polyester, nylon), size and length to ensure that it meets the hoisting requirements and meets safety standards.

How long is the service life of the sling webbing?

The service life depends on the material, frequency of use and environment. Generally, high-quality webbing can be used for several years under normal use, and if it is worn or damaged, it needs to be replaced in time.

How to maintain and care for sling webbing?

Clean regularly, check for wear, avoid direct sunlight and contact with sharp objects, and store in a dry and cool place.

What are the safety precautions for sling webbing?

Avoid overloading, severe stretching and improper knotting to ensure that the use of sling webbing is within the safe range.

Does the sling webbing need to be checked or replaced regularly?

Yes, it needs to be checked regularly, and if it is damaged or worn, it should be replaced immediately to ensure safe use.