2025-12-30 10:35:14

In the global automotive webbing market,width and thickness are not just basic physical parameters;they directly determine safety performance,comfort,durability,and compatibility with vehicle restraint systems.As vehicle safety regulations tighten and OEM requirements become more specialized,Automotive webbing dimensions have evolved from standardized ranges into highly engineered specifications.

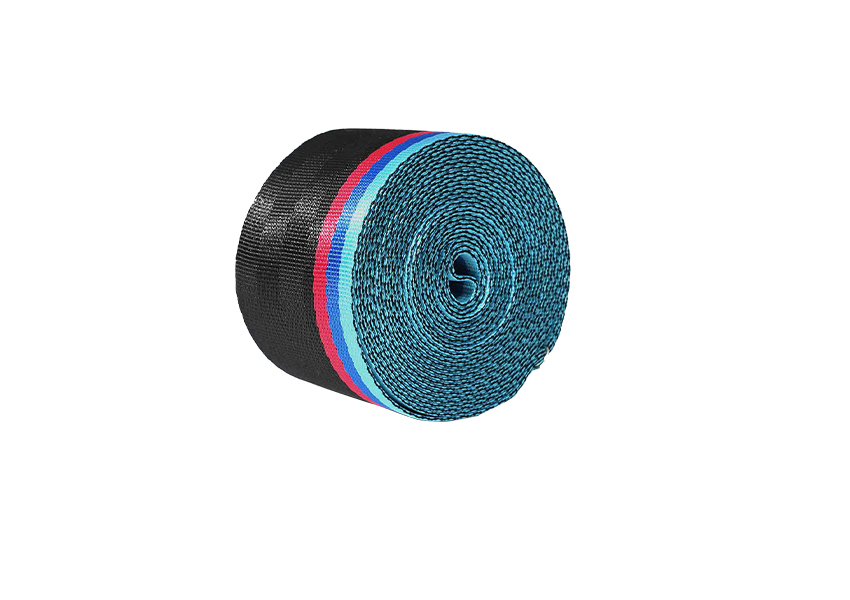

Automotive webbing is widely used in seat belts,airbags,child restraint systems,interior load-bearing straps,and various safety-related components.Each application imposes unique demands on width and thickness,shaping how manufacturers across the automotive webbing industry design and supply their products.

From a market perspective,understanding these dimensional options is essential for buyers evaluating suppliers,engineers developing new systems,and procurement teams monitoring cost and compliance within a rapidly expanding automotive webbing market.

Seat belt webbing remains the most dominant application segment in terms of volume and value.In this area,width is closely tied to international safety standards and vehicle ergonomics.The most commonly used widths typically fall between 46 mm and 49 mm,with 48 mm being the global mainstream standard.This range balances load distribution across the occupant’s body while maintaining flexibility and comfort during everyday use.In premium or specialized vehicles,slight variations may be introduced to optimize belt retraction performance or aesthetic integration with interior design.

Beyond seat belts,narrower webbing options are increasingly used in child safety systems,airbags,and interior restraint components.Widths such as 20 mm,25 mm,and 38 mm are commonly specified for these applications.These narrower webbings are engineered to handle precise loads while allowing compact packaging inside vehicle structures.As vehicle interiors become more modular and lightweight,demand for narrower yet stronger webbing continues to grow across the automotive webbing market.

Thickness,often overlooked by non-technical buyers,plays an equally critical role.Automotive webbing thickness generally ranges from 1.0 mm to over 2.0 mm,depending on yarn density,weave structure,and intended load capacity.Thicker webbing typically offers higher tensile strength and abrasion resistance,making it suitable for high-load safety systems.However,excessive thickness can negatively affect flexibility,retraction speed,and comfort,especially in seat belt systems where smooth operation is essential.

Manufacturers within the automotive webbing industry continuously optimize thickness through advanced weaving technologies rather than simply adding material.High-density weaving allows thinner webbings to achieve equal or superior strength compared to older,thicker designs.This evolution supports broader automotive industry trends toward lightweighting without compromising safety,a key driver influencing the automotive webbing market size globally.

Customization has become a defining characteristic of modern automotive webbing supply.OEMs increasingly request specific width and thickness combinations tailored to vehicle platforms,regional regulations,or branding requirements.For example,electric vehicles often require webbing with optimized thickness to accommodate unique cabin layouts and energy-absorbing structures.This shift toward customization has transformed width and thickness from fixed parameters into strategic design variables.

Regional market differences also influence dimensional preferences.In North America and Europe,stringent crash safety regulations favor webbing dimensions with higher load margins,while Asia-Pacific markets often prioritize manufacturing efficiency and cost optimization.These regional dynamics directly impact the automotive webbing market size and production strategies adopted by global suppliers.

From a sourcing perspective,buyers evaluating automotive webbing suppliers should consider not only nominal width and thickness values but also tolerance control and consistency.Even minor dimensional deviations can affect system performance,especially in automated assembly lines.Leading manufacturers invest heavily in quality control systems to ensure dimensional stability across large production volumes,reinforcing their competitiveness within the automotive webbing industry.

As vehicle safety technology continues to advance,width and thickness options will further diversify.Smart restraint systems,adaptive seat belts,and next-generation airbag designs all require precisely engineered webbing dimensions.These innovations are expected to contribute to sustained growth in the automotive webbing market,expanding both application scope and overall automotive webbing market size in the coming years.

In conclusion,width and thickness in automotive webbing are no longer simple specifications but integral elements of safety engineering and market differentiation.For stakeholders across the automotive webbing industry,a deep understanding of these parameters is essential to remain competitive in an increasingly sophisticated automotive webbing market.